Wind farm support vessel foam filled fenders

WFSV are dedicated to transport maintenance team to offshore wind farms. Its maximum capacity is 12 persons with the possibility of carrying light cargo parcels on the offshore fields. WFSV needs to meet high requirements such as:

- Light, high speed and comfortable for personnel

- Highly manoeuvrable boats with good sea keeping capabilities

- Reliable, facing potential difficult sea conditions

- Manoeuvrability & station keeping characteristics make it perfect vessel for boat landing operation

Foam filled fender is highly recommended, being the best compromise between weight and capacity of absorbing shocks generated by berthing.The bow fender usually suits the wind turbine boat landing.

With our innovative solution, the WFSV is protected by foam filled fender coated with polyurethan with an additional protection calls NibraPAD© against shock generated during boat landing. It is fixed and built in on the foam filled fender, tightened with cargo straps.

Foam filled fender has many advantages, that’s why most of pilot boats are equipped with this type of fenders.

Lightweight

One third lighter than rubber fender.

Where vessel weight is of a prime importance, foam filled fender will significantly reduce overall weight without reducing protection. Lightweight fender also have a direct impact on oil consumption of workboats.

Protecting your vessel

Our foam filled fender ensure maximum protection with a very high energy absorption & low reaction force.

Our design office provide calculation note taking consideration of customer’s berthing conditions.

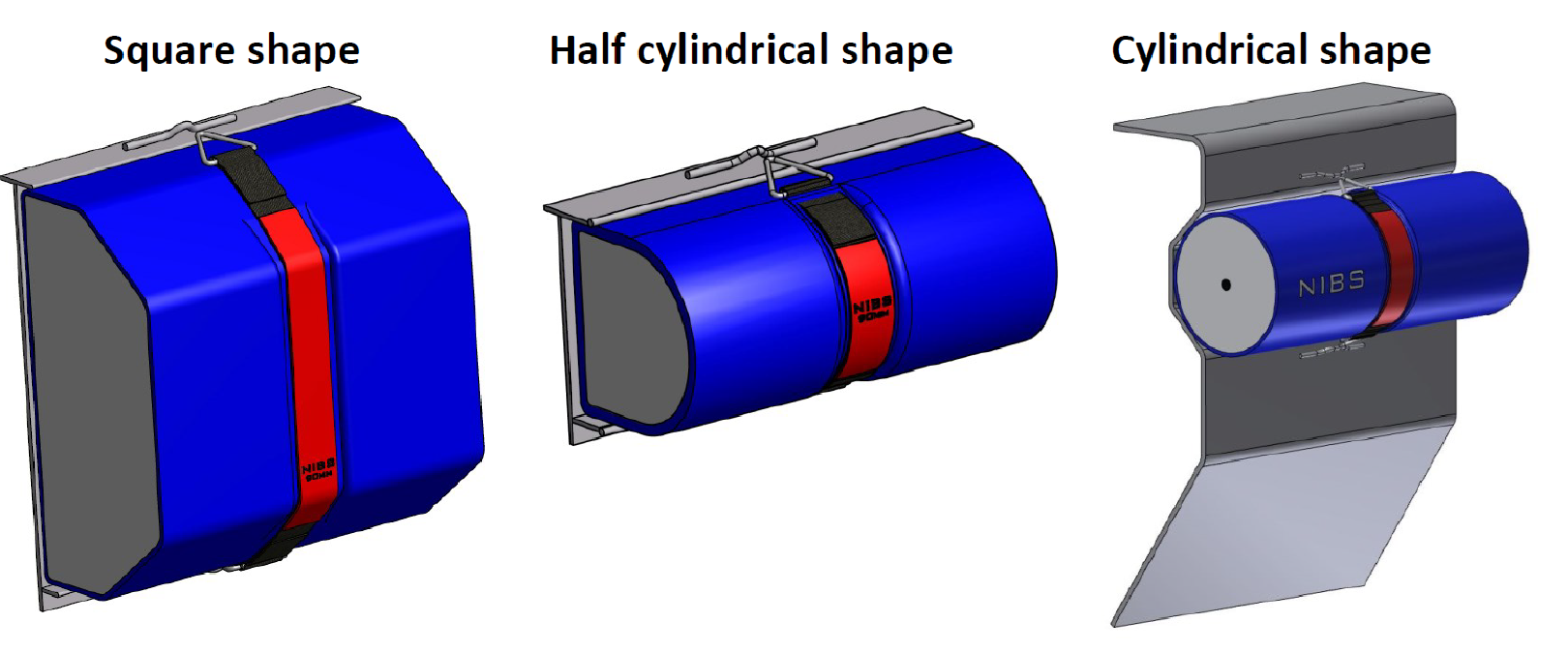

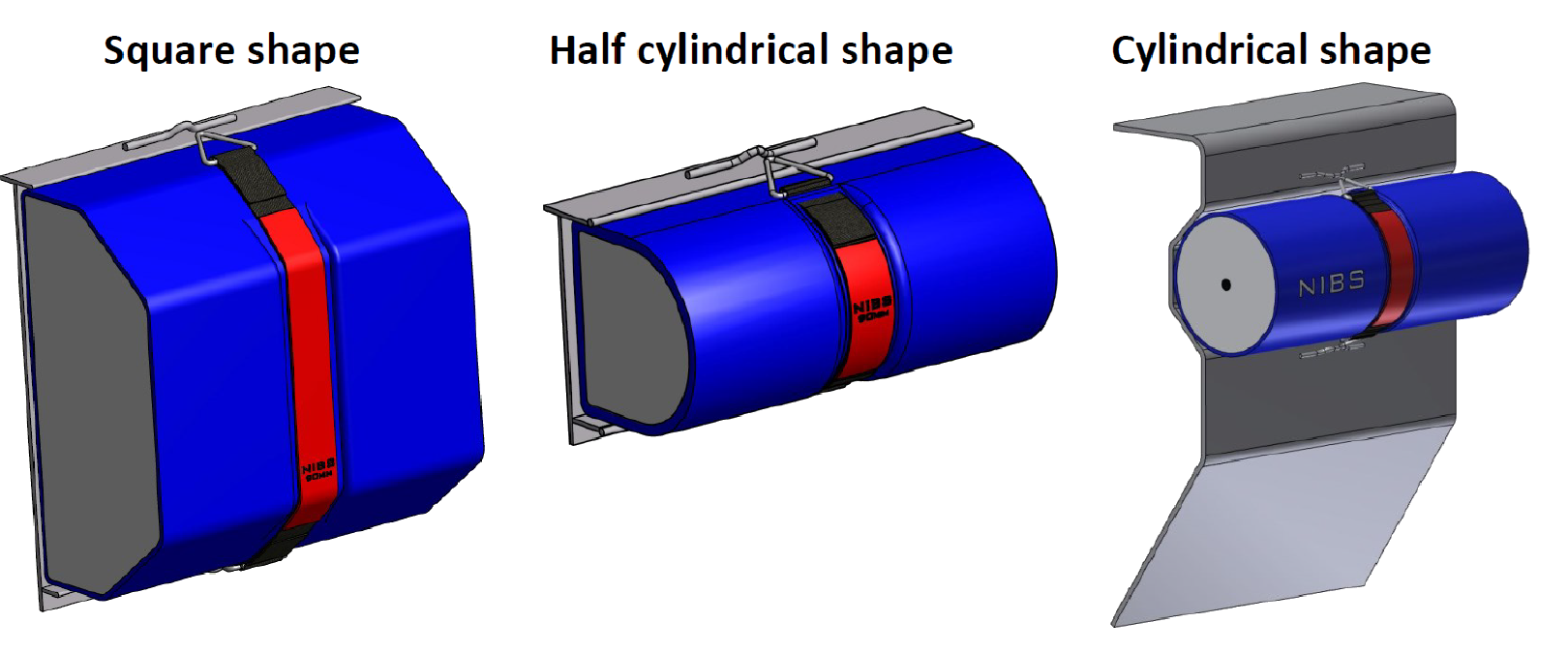

Using the 3D drawing of our customers, we advise and supply the fenders in different forms according to the available recess of the boat:

- Square shape

- Half cylindrical shape

- Cylindrical shape

No solvent use

The sprayed Nibaprene® ES 40D coating is produced without solvent, respectful of the environment, securing dimensional stability over time of the fenders while improving the resistance qualities.

Main features of boat foam filled fender

- Unsinkable, even damaged,

- Lightweight and efficient berthing properties,

- Choice of foam density to customize boat fendering system according to berthing conditions,

- Better spread of kinetic energy absorption,

- Low maintenance and no pressure monitoring required,

- Wide operating temperature range,

- Repairable.